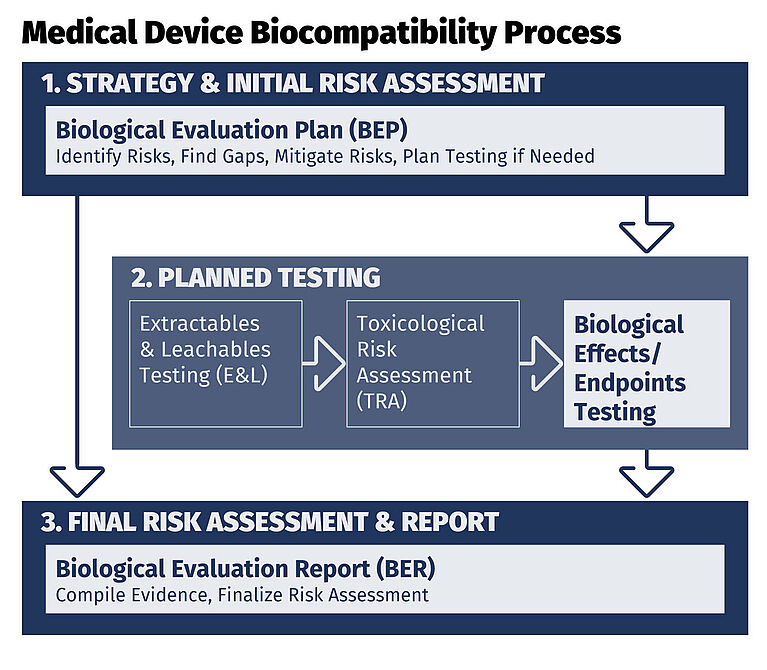

Medical Device Biocompatibility Process

Biological safety evaluation is conducted using a structured, evidence-based approach:

- A Biological Evaluation Plan (BEP) identifies biological hazards, applicable biological effects/endpoints, existing data and data gaps

- If gaps are identified, risk-based biological testing is performed to address potential harms

- Depending on materials and exposure, this may include:

- Extractables and leachables (E&L) studies

- Toxicological risk assessment (TRA)

- All data and rationale are compiled into a Biological Evaluation Report (BER), which documents:

- Biological effects/endpoints evaluated

- Risk acceptability

- Overall biological safety and regulatory compliance