BÖNNIGHEIM, GERMANY (June 5, 2019) – The 2019 published DIN SPEC 60015 “Quantitative measurement of the evaporative heat loss of smart textile materials for work, sports / outdoor and leisure” defines the measuring procedure and requirements for textiles and clothing that claim to have a cooling effect. This already offers a market compliant standard. The next stage is to convert the method into an ISO standard.

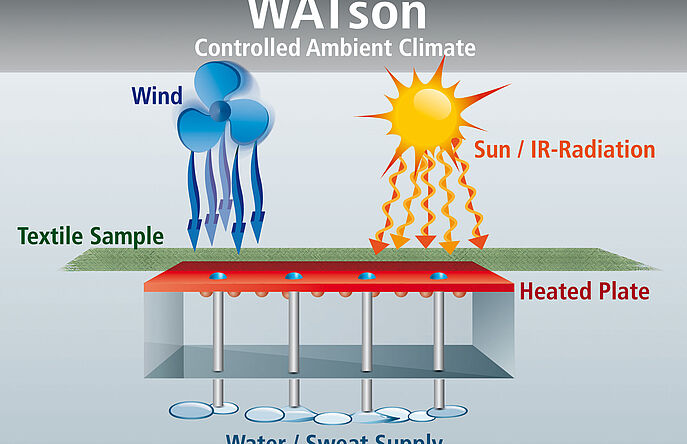

WATson is the only device worldwide that can quantitatively measure the evaporative cooling ability of a textile or textile system and is already well received in the performance apparel and home textiles industries. It measures the dynamic interaction of textiles and human thermal regulation with customizable climatic conditions and sweat rates.

Only a 25x25 cm fabric sample is required for the WATson test, which provides data on average cooling power, cooling power over time, fabric response and dry time. The data is used for product development, benchmark comparisons, quality assurance and verified marketing claims.

In addition to the measurement scenarios defined in DIN SPEC 60015, WATson’s setup can be tailored to meet specific requirements.

###

With more than 40 offices and laboratories worldwide, Hohenstein is an international testing partner in the textile industry. Hohenstein’s research centers around the interaction between textiles, humans and the environment. It is a founding member and leading provider of the OEKO-TEX® portfolio of services such as the STANDARD 100 by OEKO-TEX® certification, the international standard for safe textiles, and is certified by the U.S. Consumer Products Safety Commission as a third-party, independent laboratory for CPSIA compliance verification. Hohenstein.US